Sieve Bend Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSC Screen can be custom designed to separate solids from liquids in various appli-cations including food processing, pulp and paper, waste water clean up, surface water intakes, corn wet milling, coal preparation, and gold recovery.

Sieve Bend Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSC Screen can be custom designed to separate solids from liquids in various appli-cations including food processing, pulp and paper, waste water clean up, surface water intakes, corn wet milling, coal preparation, and gold recovery.

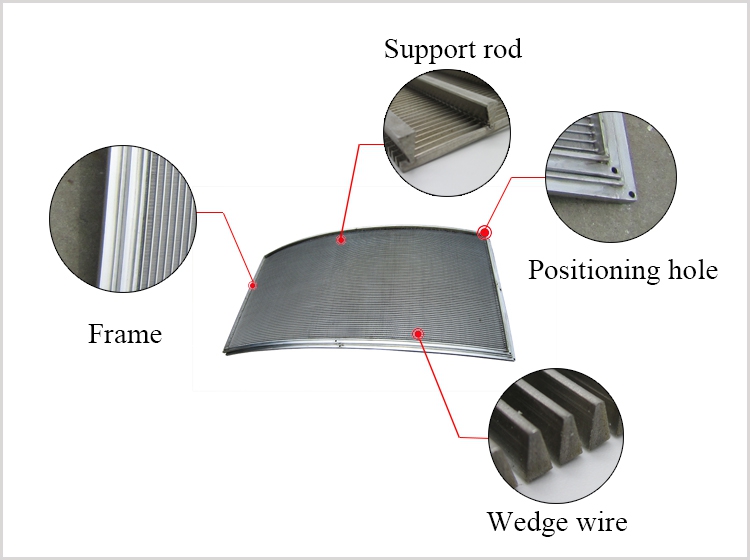

Sieve Bends are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

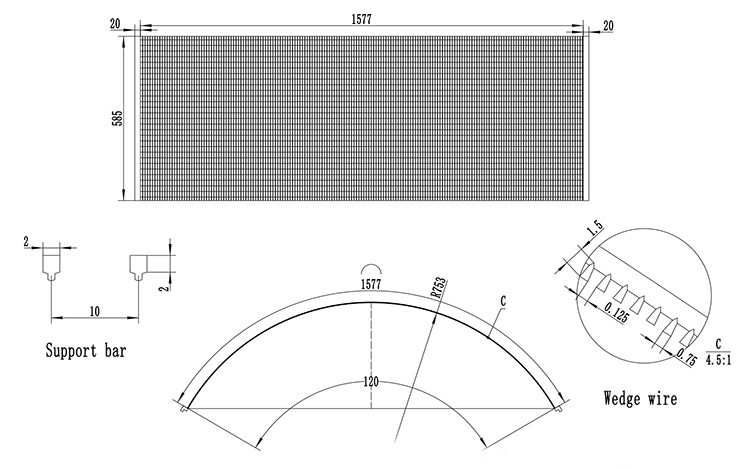

Curved Profile: Sieve bend screens have a curved or concave surface, which allows for effective and efficient screening and dewatering. The curve typically ranges from 30 to 180 degrees, depending on the specific application.

Slot Openings: They are made from profile wires or wedge wires with precise slot openings. The slot size can be customized to suit the particle size distribution of the material being processed.

High Screening Efficiency: Sieve bend screens offer high screening efficiency due to their unique design. The curved surface and precise slot openings facilitate the separation of solids from liquids, making them ideal for fine particle separation.

Dewatering: These screens are often used for dewatering applications, such as in wastewater treatment plants and the processing of slurries and industrial effluents.

Low Maintenance: Sieve bend screens are known for their durability and low maintenance requirements. They are resistant to clogging and blinding, which can be common issues with other types of screens.

Customization: Sieve bend screens can be customized in terms of curvature, slot size, and material of construction (e.g., stainless steel) to meet the specific needs of the application.

Sieve bend screens find application in various industries and processes, including:

Wastewater Treatment: They are commonly used in wastewater treatment plants for the removal of solids from sewage and industrial effluents.

Mining and Mineral Processing: Sieve bend screens are used in mining operations to separate and dewater coal, minerals, and ores.

Food and Beverage Industry: They can be used for food processing applications, such as separating solid particles from liquids in fruit and vegetable juice production.

Pulp and Paper Industry: Sieve bend screens are used in pulp and paper mills to dewater pulp and recover fibers.

Chemical Processing: They find application in chemical processing industries for solid-liquid separation and dewatering of chemical solutions and slurries.

Sugar Industry: Sieve bend screens are used in sugar mills for the separation of bagasse from juice during the sugar extraction process.

Agriculture: They can be used in agricultural applications for separating solids from liquid manure or effluent.

| Material | SS304, SS 304L, SS 316, SS316L, SS321, Duplex, Hastelloy, etc | ||||||

| Width | Up to 6000mm | ||||||

| Length | Up to 6M | ||||||

| Slot | Min.20 micron, to 3000 micron | ||||||

| Wedge wire | 0.5*1.5 | 0.75*1 | 1*2 | 1.5*2 | 2*3 | 2*4 | 3*5 |

| Support wire | 1.5*2.5 | 1.5*2.5 | 1.5*2.5 | 1.8*2.5 | 2*3 | 2*4 | 3*5 |

| 2*3 | 2*3 | 2*3 | 2*3 | 2*4 | 3*5 | 3*6 | |

| 3*5 | 3*6 | 3*10 | |||||

| 3*6 | 3*10 | 4*7 | |||||

| 3*10 | 4*7 | 5*6 | |||||

| 4*7 | 5*6 | 5*8 | |||||

| End | Flange, metal ring, cross connector, closed, etc | ||||||

| Note | Customized is available | ||||||

| The following dimensions are for reference | ||||||||||

| V-wire | 20 | 30 | 47 | 60 | 68 | 90 | 118 | 130 | 158 | 191 |

| Width | 0.50 | 0.76 | 1.19 | 1.52 | 1.80 | 2.26 | 2.95 | 3.30 | 4.01 | 4.95 |

| Height | 1.01 | 1.27 | 2.23 | 2.54 | 4.50 | 3.50 | 4.70 | 6.35 | 6.07 | 9.22 |

| Support rod | 63 | 025 | 93 | XJR | 156 | SR250 | SR475 |

| Width | 1.52 | 1.00 | 2.26 | 2.26 | 3.84 | 2.50 | 2.50 |

| Height | 2.54 | 1.50 | 3.51 | 4.80 | 5.51 | 5.60 | 6.30 |

Detail picture

Drawing

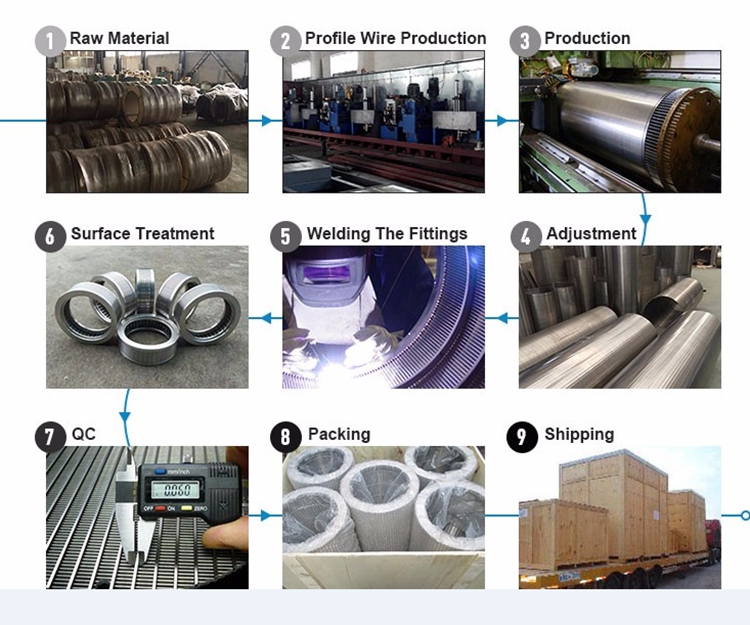

Products Process

Test

Packing

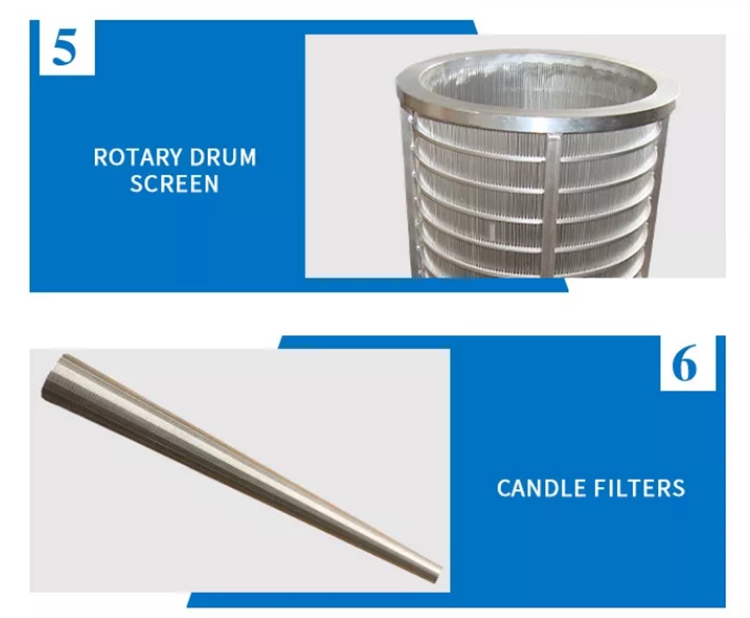

Related Products

Tags:

Related Products