Polyester Plain Weave Mesh Conveyor Belts Linear Screen Cloth Conveyor Belts For Drying Mining

It have the characteristics of tear-resistance, shrink-resistance and abrasion resistance etc. Polyester Monofilament process conveyor belting is available in a wide variety of yarn thicknesses and apertures.

Description

Polyester Plain Weave Mesh Conveyor Belts Linear Screen Cloth Conveyor Belts For Drying Mining

It have the characteristics of tear-resistance, shrink-resistance and abrasion resistance etc. Polyester Monofilament process conveyor belting is available in a wide variety of yarn thicknesses and apertures. Polyester mesh belting is characterised by high reliability, easy handling, thermal and chemical resistance coupled with dimensional stability.

Specification

| Wire diameter(mm) | Density(wire/centimeter) | Strength (N/cm) | weight(kg/m2) | Thickness (mm) | Mesh Radial/latitude(mm) | Aperture Radial/latitude(mm) | permeability(m3/m2/h) | CFM/127Pa | open aven | |||

| warp | weft | warp | weft | surface | joint | |||||||

| 1 | 1 | 2.85 | 2.65 | 1600 | 650 | 0.6 | 1.85 | 7.10/6.73 | 2.50/2.77 | 32000 | 2000 | 52.55 |

| 1 | 1 | 3.2 | 3.25 | 1600 | 650 | 0.8 | 1.86 | 8.10/8.20 | 2.12/2.07 | 25600 | 1600 | 45.9 |

| 0.9 | 0.9 | 3.9 | 3.65 | 1600 | 650 | 0.55 | 1.7 | 9.60/9.30 | 1.66/1.83 | 20000 | 1250 | 46.58 |

| 0.9 | 0.9 | 4.65 | 4.7 | 1600 | 650 | 0.95 | 1.66 | 44542 | 1.25/1.22 | 17600 | 1170 | 33.55 |

| 0.5 | 0.6 | 4.4 | 5.2 | 1600 | 650 | 0.58 | 1.23 | 12/13.2 | 1.72/1.32 | 19000 | 1187 | 53.32 |

| 0.6 | 0.6 | 5.9 | 5.6 | 1600 | 650 | 0.62 | 1.1 | 14.98/14.2 | 1.09/1.18 | 18000 | 1125 | 42.89 |

| 0.8 | 0.8 | 5.1 | 5.3 | 1600 | 650 | 0.89 | 1.48 | 13/13.5 | 1.16/1.08 | 15840 | 990 | 34.09 |

| 0.65 | 0.65 | 7.4 | 6.8 | 1600 | 650 | 0.65 | 1.19 | 18.8/17.3 | 0.70/0.82 | 14400 | 1190 | 28.96 |

| 0.8 | 0.8 | 6.6 | 6.5 | 1600 | 650 | 0.85 | 1.45 | 16.8/16.5 | 0.72/0.73 | 11600 | 725 | 22.65 |

| 0.7 | 0.7 | 7 | 7 | 1600 | 650 | 0.77 | 1.3 | 17.8/17.8 | 0.72/0.72 | 11000 | 690 | 26.01 |

| 0.8 | 0.8 | 7.8 | 7 | 1600 | 650 | 1.1 | 1.45 | 20.3/18 | 0.32/0.54 | 5920 | 370 | 16.54 |

| 0.5 | 0.5 | 9.7 | 10.3 | 1600 | 650 | 0.5 | 0.9 | 25/26.2 | 0.53/0.47 | 10100 | 634 | 24.97 |

| 0.5 | 0.5 | 13.5 | 8.5 | 1600 | 650 | 0.63 | 0.95 | 34.3/21.6 | 0.24/0.65 | 6500 | 6280 | 18.68 |

| 0.45 | 0.45 | 10 | 8.6 | 1600 | 650 | 0.45 | 0.88 | 25.4/21.8 | 0.55/0.71 | 15570 | 970 | 33.71 |

| 0.5 | 0.6 | 9.4 | 9 | 1600 | 650 | 0.6 | 0.95 | 23.8/23.1 | 0.56/0.51 | 9000 | 560 | 24.38 |

| 0.5 | 0.5 | 9.5 | 8.6 | 1600 | 650 | 0.89 | 0.47 | 24.13/21.8 | 0.50/0.65 | 10140 | 634 | 29.93 |

| 0.7 | 0.8 | 7 | 5.5 | 1600 | 650 | 0.75 | 1.53 | 17.8/14 | 0.72/1.0 | 16000 | 1000 | 28.56 |

| 1 | 1 | 4.5 | 5.5 | 1600 | 650 | 0.65 | 1.63 | 17/14 | 0.35/0.60 | 5920 | 370 | 14.85 |

| 0.5 | 0.6 | 10.5 | 9.2 | 1600 | 650 | 0.65 | 1.05 | 26.67/23.4 | 0.45/0.48 | 8300 | 518 | 44.87 |

| 0.8 | 0.8 | 8 | 8 | 1600 | 650 | 1.15 | 1.66 | 20.3/20.3 | 0.45/0.45 | 6400 | 400 | 16.26 |

| 0.8 | 0.9 | 7.6 | 6.5 | 1600 | 650 | 1.25 | 1.76 | 19.3/16.5 | 0.51/0.63 | 9184 | 574 | 12.96 |

| Weaving Type | Thread Diameter(mm) | Density(No.s/cm) | Srength (N/cm) | Air Permeability (m³/m²h) | ||

| Warp | Weft | Warp | Weft | |||

| 2-shed plain weaving fabric | 0.75 | 0.8 | 4.7-5 | 4.8-5 | 940 | >20000 |

| 1.0 | 1.0 | 4.7-5.2 | 4.3-5 | 1600 | >15000 | |

| 0.7 | 0.7 | 8 | 7 | >=1600 | 11000 | |

| 0.7 | 1.0 | 6.6-7 | 4.3-4.6 | 1100 | >15000 | |

| 0.55 | 0.55 | 7.5-8 | 8.5-9 | 850 | 850-6500 | |

| 0.45 | 0.45 | 10 | 8.6 | 1600 | 16000 | |

| 0.5 | 0.5 | 8.5-9 | 10-10.5 | 750 | >10000 | |

| 0.5 | 0.5 | 13.5 | 8.5 | 1800 | 6500 | |

| 3-shed plain weaving fabric | 0.5 | 0.6 | 10 | 9 | 1600 | 14000 |

| 0.9 | 0.9 | 7.8-8 | 5-5.5 | 2100 | 7500-8500 | |

| 0.7 | 0.8 | 8 | 8 | 1600 | 10000 | |

| 0.3 | 0.35 | 22 | 14.5 | 1200 | 13000 | |

| 0.3 | 0.4 | 22 | 14.5 | 1200 | 13500 | |

Product Picture

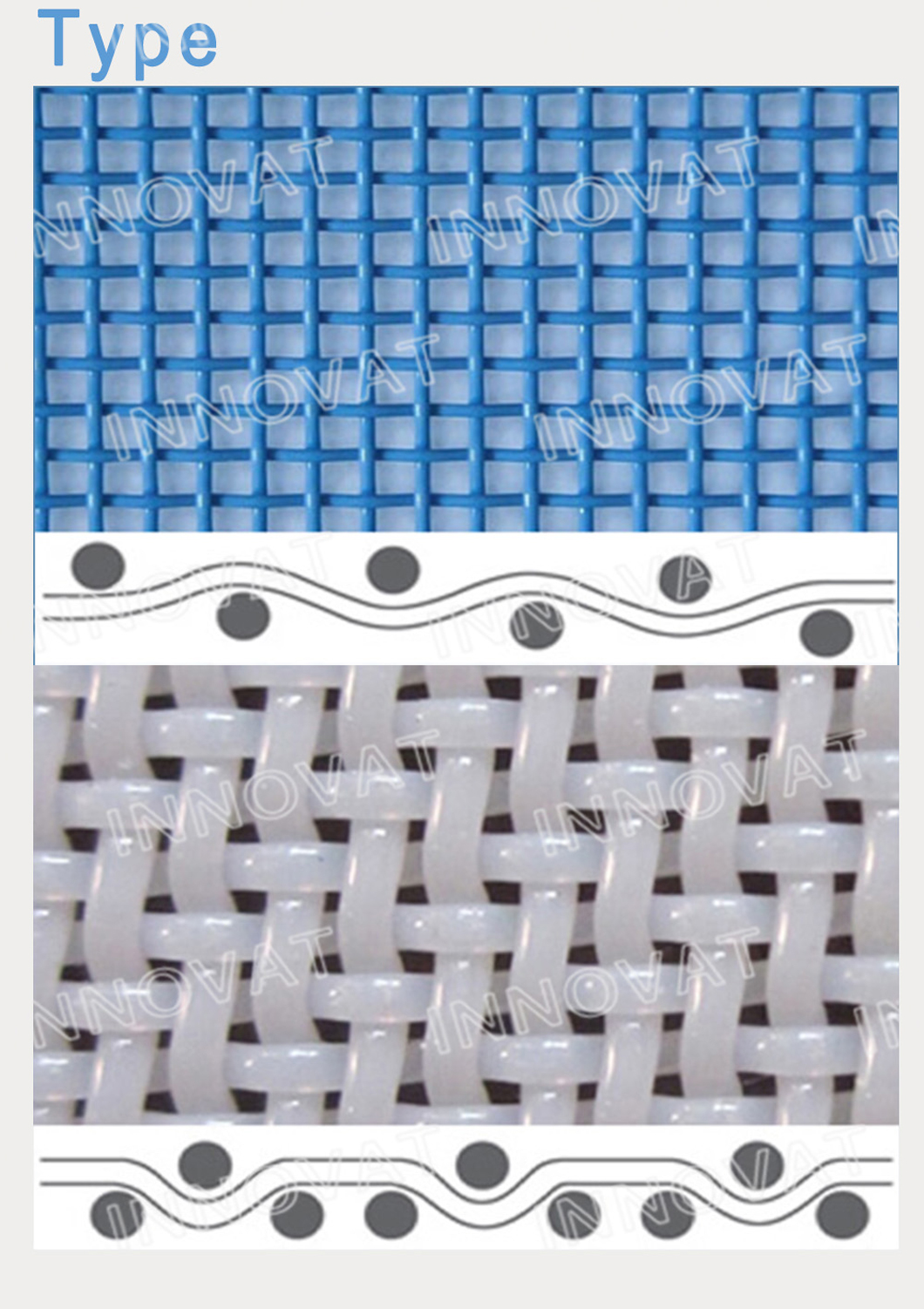

Type

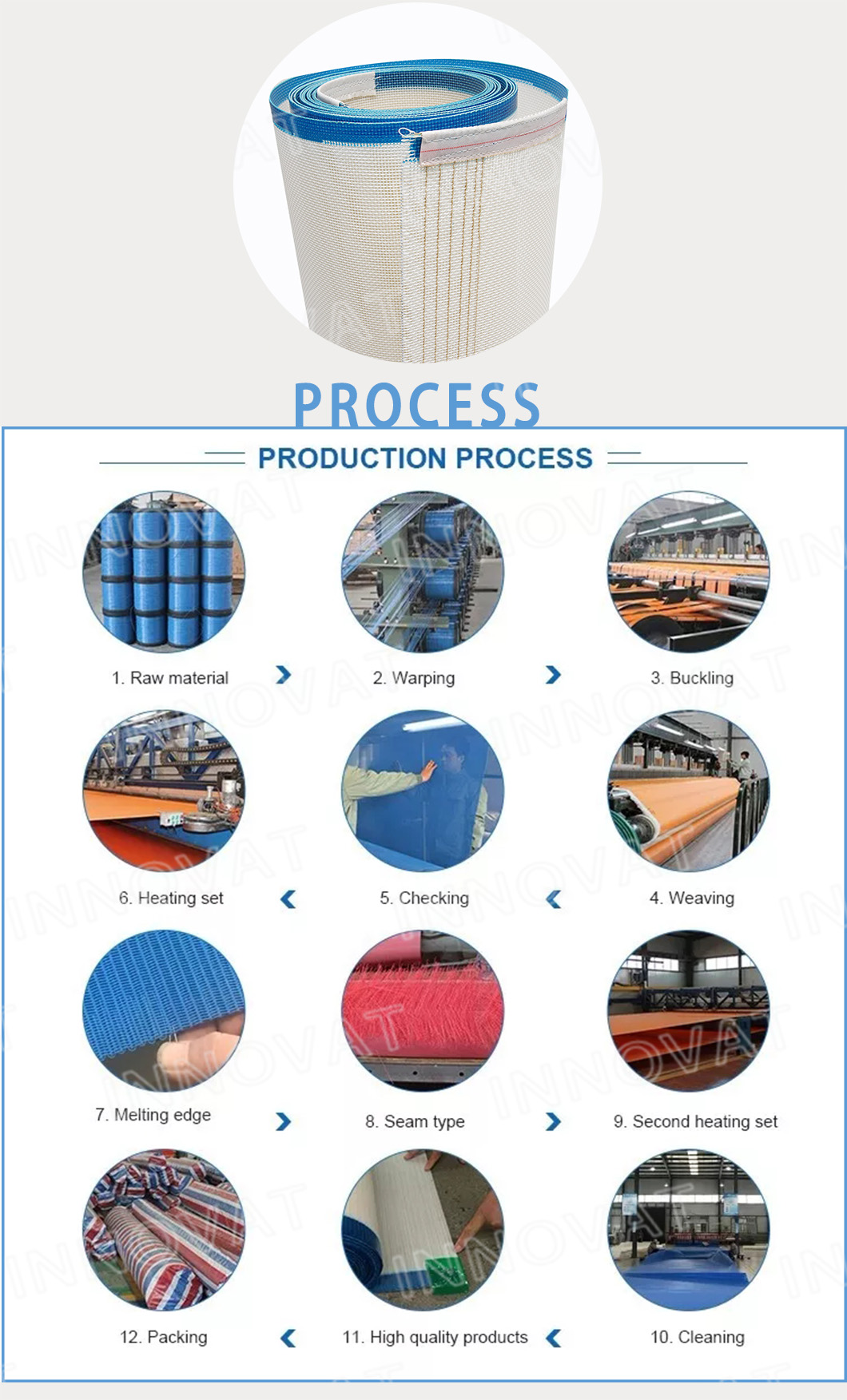

Process

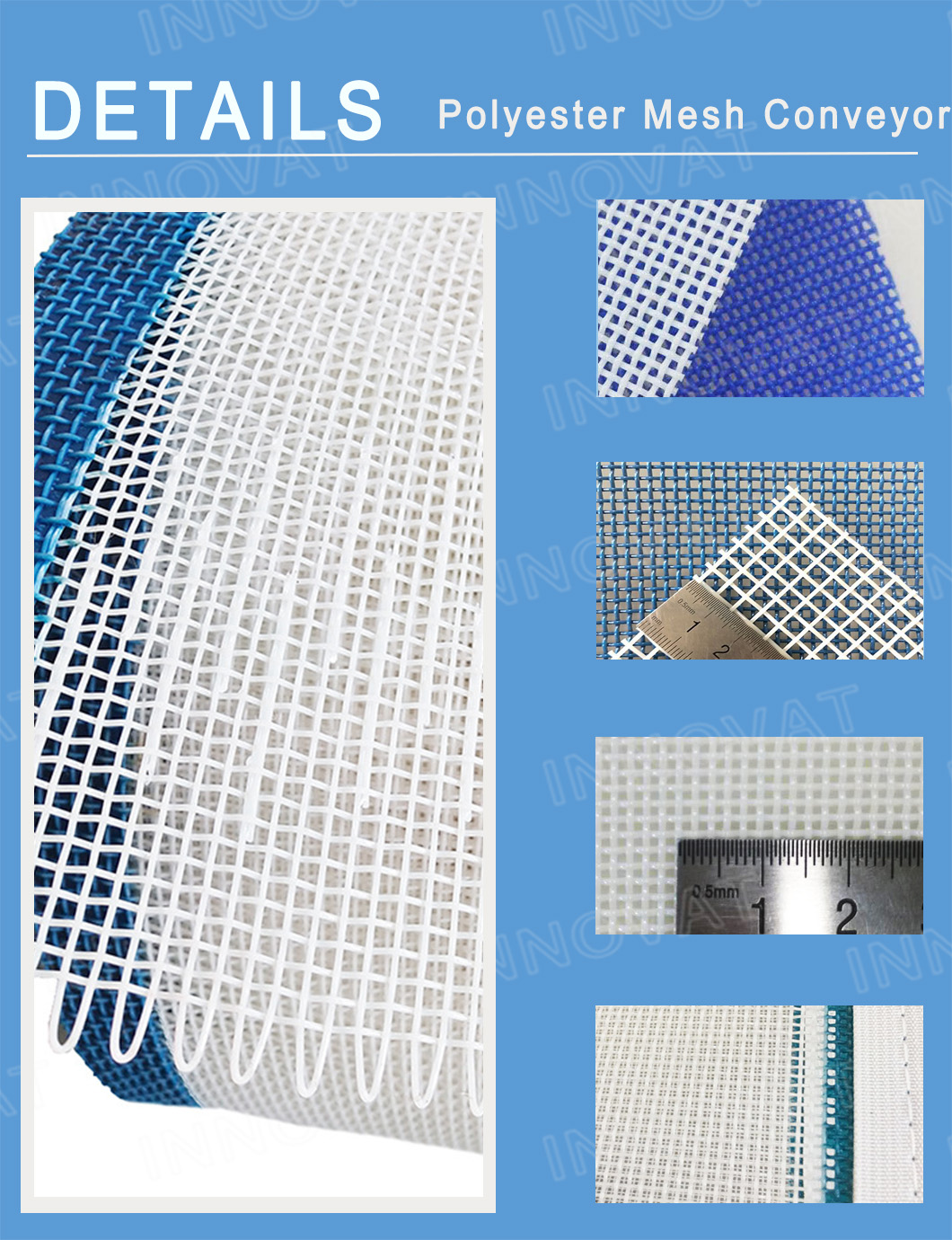

Details

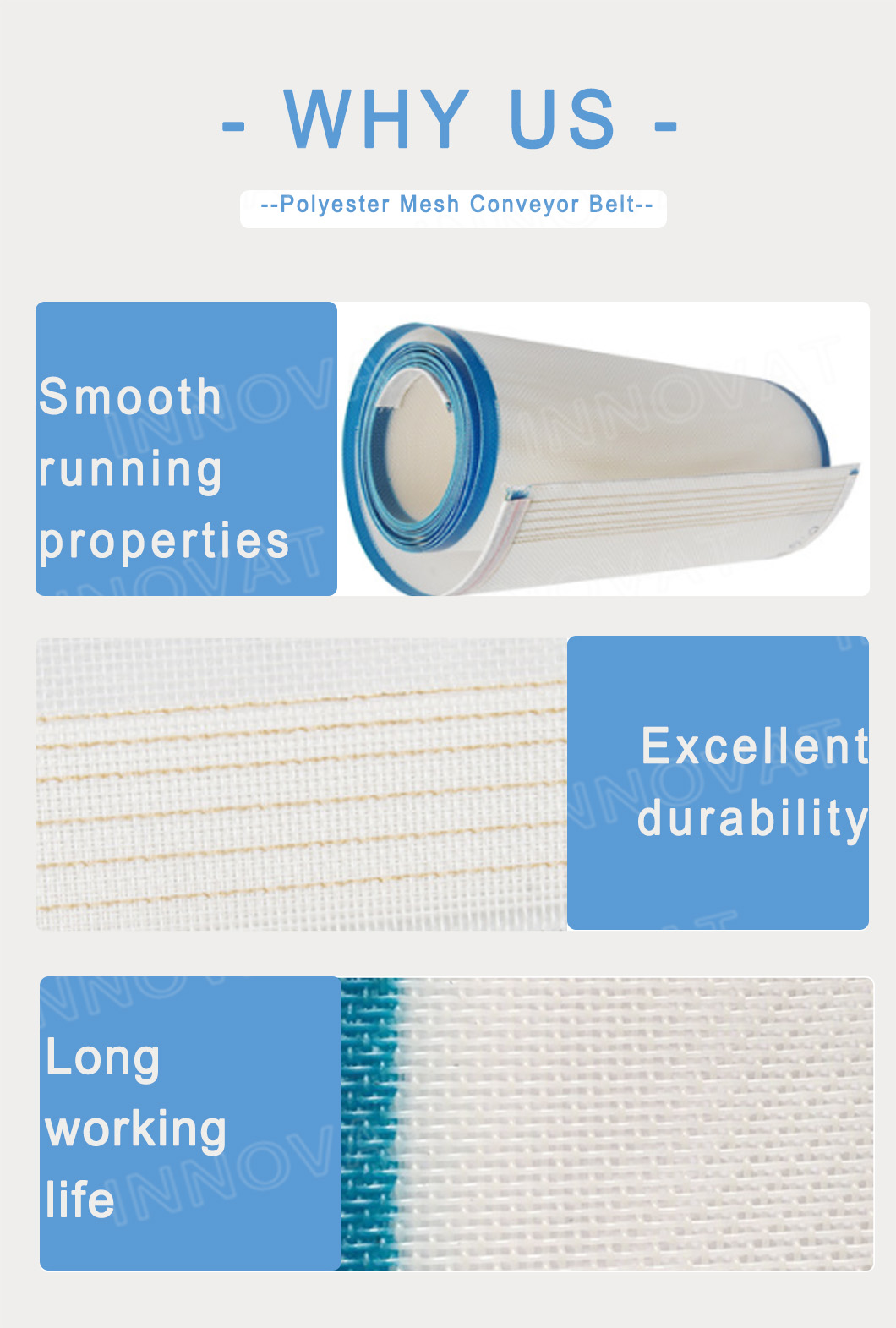

Why Us

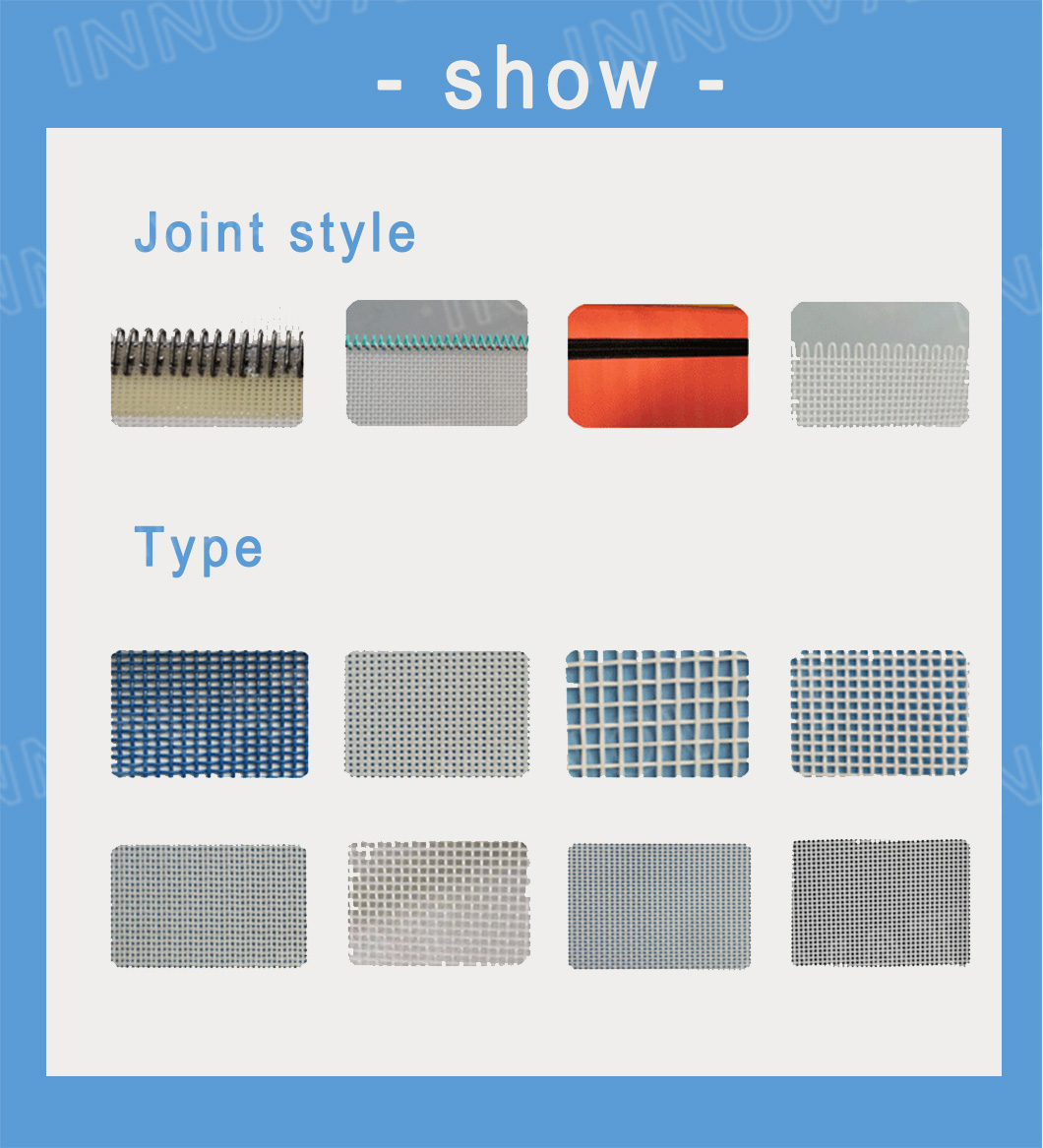

Show

Feature

Material Properties

1) Excellent chemical, thermal and high permeability for ease of cleaning

2) Food approval

3) Working temperature: +150°C to -75°C in dry conditions. 70°C+ in wet conditions

4) Precise aperture to achieve excellent filtration results and efficiency

5) Smooth running properties

6) Mesh opening 0.4mm-5.0mm available

7) Excellent chemical stability, Synthetic Fiber Chemical Properties Table

8) Excellent durability

9) Max. Width 6.0 M with hot melt edges

10) Clipper seam, pin rings, spiral rings, endless connection type are all available

Application

● Pulp boards making.

● Wood industry: Dryer belts of woodchips, particle boards, MDF/HDF, etc.

● Nonwoven cloth industry.

● Food drying.

● Material screening and separation.

● Environment protection: sludge dewatering in belt press filters.

● The pre-cleaning process before fruit and vegetable processing

Tags: