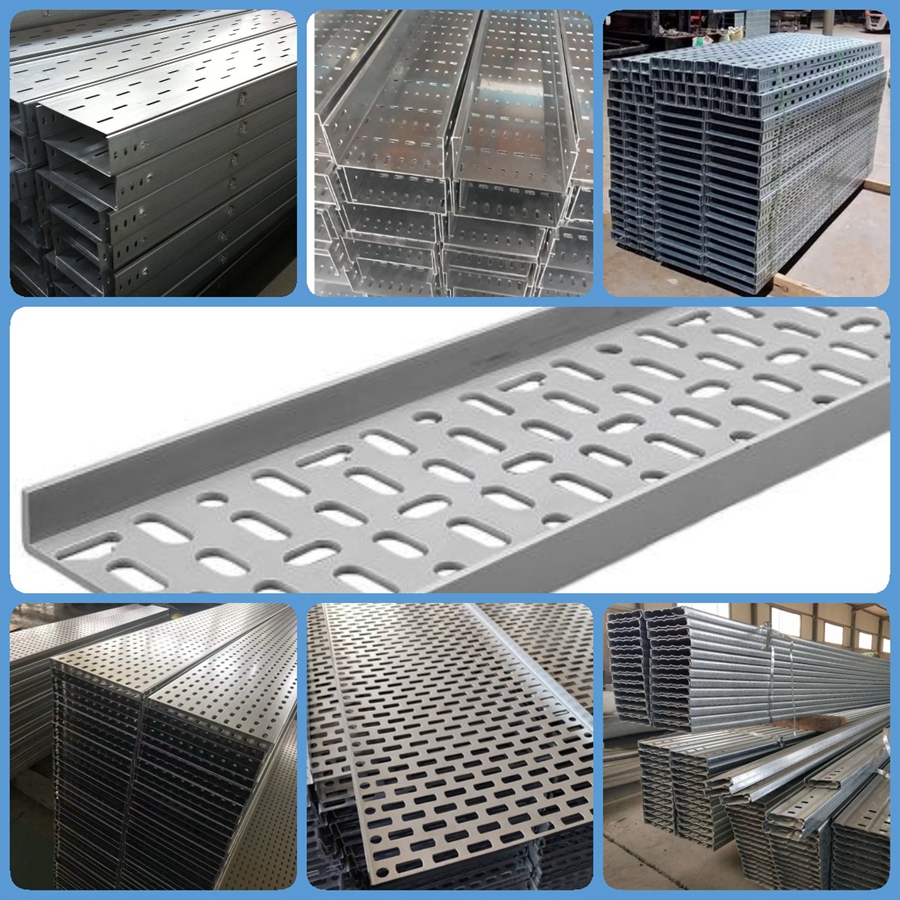

Perforated cable tray has a similar structure with the cable trunking. There are a series of holes on the bottom and side walls. It has different hole patterns, such as oval, slot, round and other types. The holes make the perforated cable tray a good air circulation and heat dispersion.

Description

Perforated cable tray has a similar structure with the cable trunking. There are a series of holes on the bottom and side walls. It has different hole patterns, such as oval, slot, round and other types. The holes make the perforated cable tray a good air circulation and heat dispersion.

Perforated cable tray has different types according to different side walls. The main side walls can be R type inside flange, R type outside flange, C type inside flange, C type outside flange and P type. The various types can let the perforated cable tray suit more applications and supply more choice for the customers.

Specification

| Material | Steel or Customized vertical metal strut cable tray |

| Width | 50mm, 100mm, 150mm, 200mm, 250mm, 300mm,450mm, 600mm, or as you required. |

| Height | 15mm, 50mm, 75mm, 100mm, or as you required. |

| Length | 3000mm, 6000mm, or as you required. |

| Thickness | 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 2.5mm, 3mm, or as you required. |

| Raw Materials | Q235, SS304, SS316, Aluminum, FRP |

| Surface Finish | Hot Dipped Galvanized – for outdoor use to BS EN 1461-1999Electro zinc plated – for indoor use to BS EN 12329-2000 Electrolytic Polishing – for stainless steel use Powder coating-for indoor and ourdoor use |

Features

Different sizes, forms and fitting for your demands

Specially engineered for cable protection and good ventilation

Heavy load, simple structure

Beautiful finish, optimum quality

Good air circulation, water drainage or dust free falling

Suitable for electrical, network and fibre cables, etc

Quick and flexible cable deployment

Easy to install and fix with brackets

ODM or OEM are available

High quality, competitive factory price

Details

Process

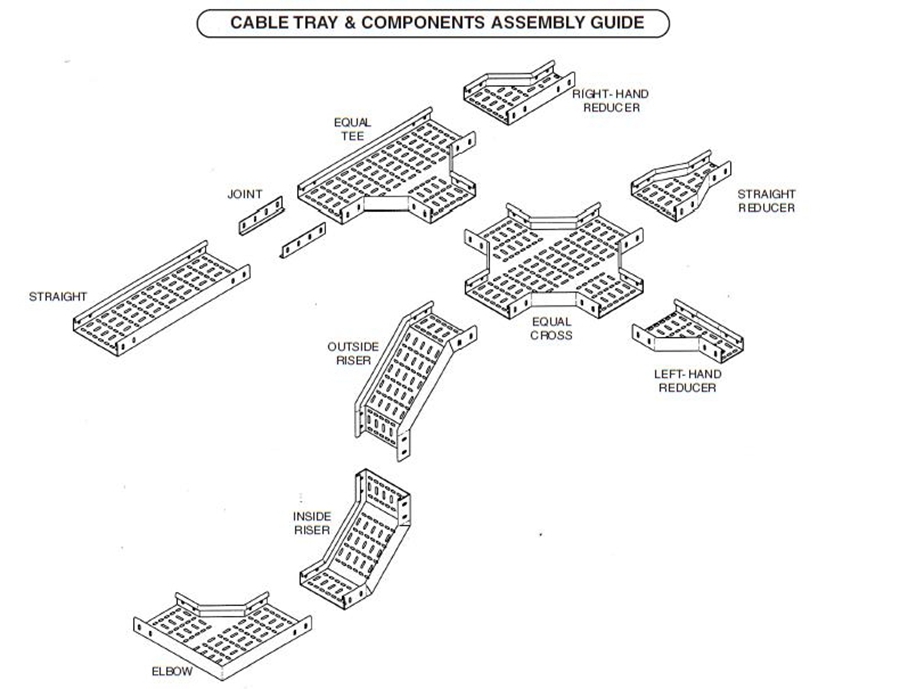

Drawing

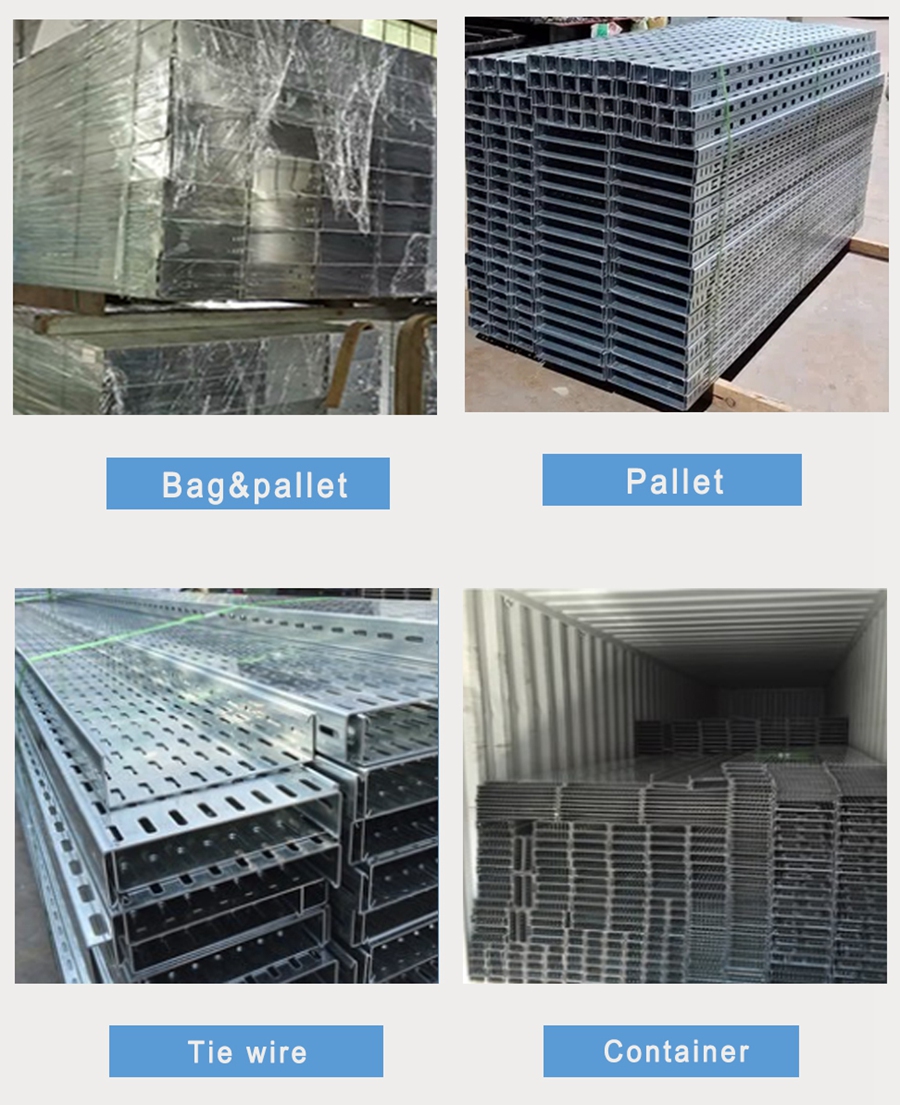

Packing

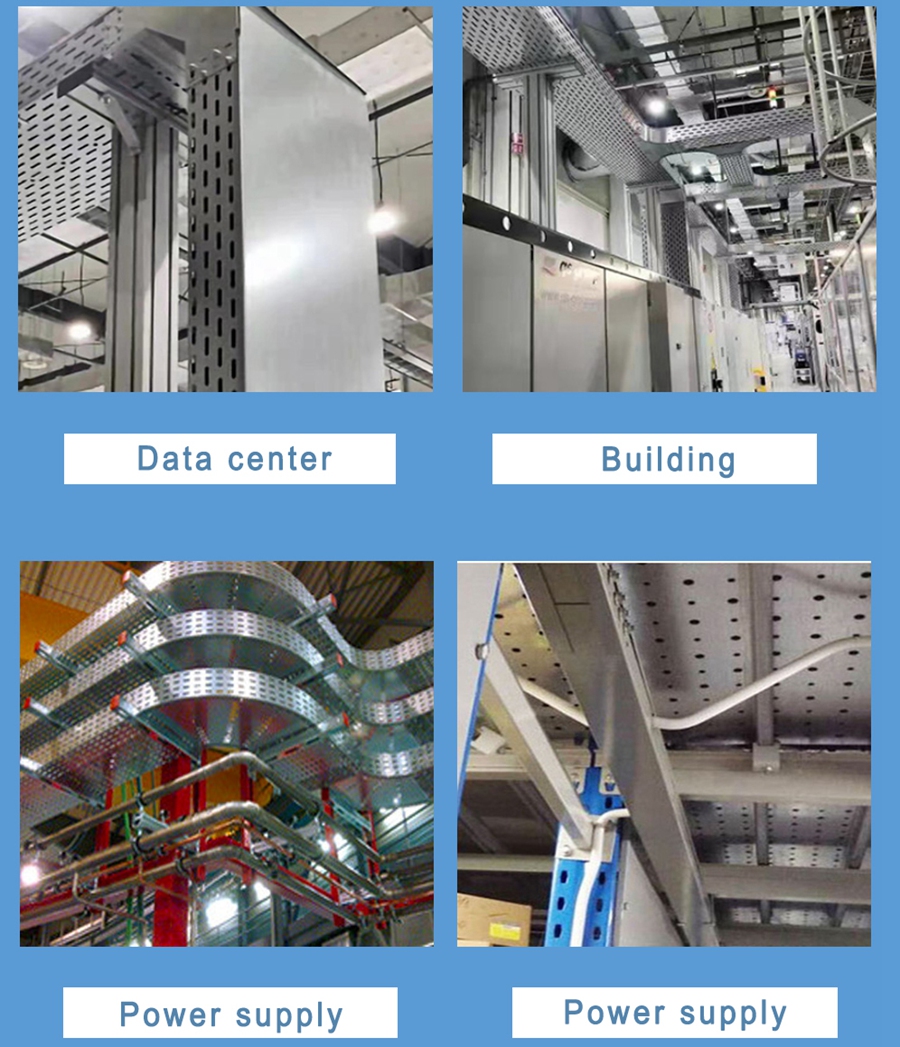

Application