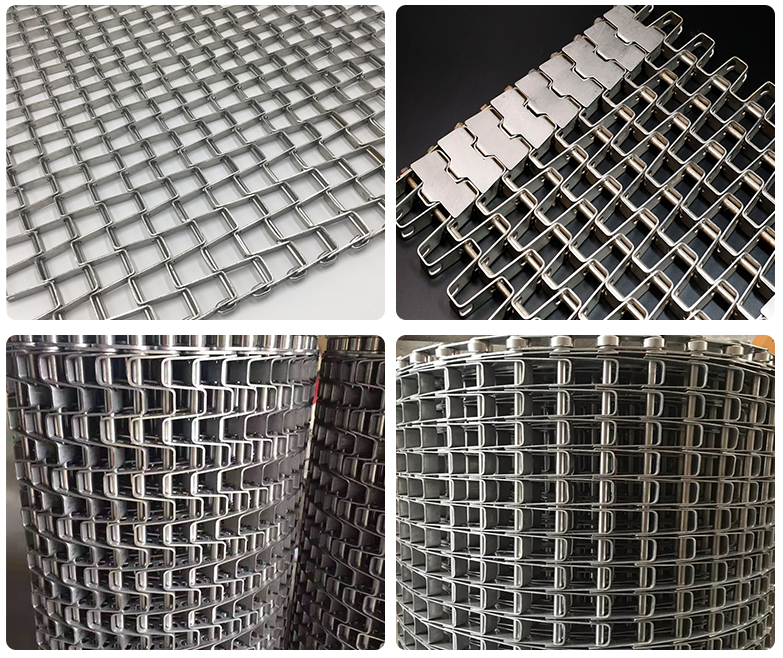

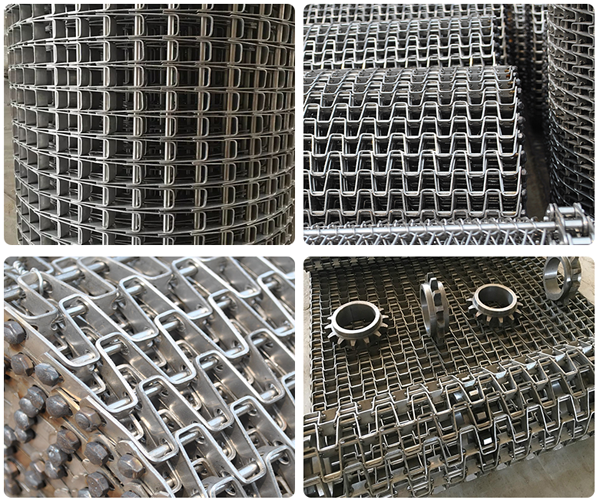

Great Wall Wire Belt is constructed of cross rods and a flat metal strip. At the sides of the belt the cross rods have a welded ring (welded edges). In a number of dimensions it is possible to give the sides of the belt a clinched edge. There are a number of predefined belt executions with different pitches and material dimensions. The belt can also be provided with side plates or flights.

Product Introduction

Great Wall Wire Belt, also called Flat Wire Conveyor Belt, Honeycomb conveyor belt.

Great Wall Wire Belt is constructed of cross rods and a flat metal strip. At the sides of the belt the cross rods have a welded ring (welded edges). In a number of dimensions it is possible to give the sides of the belt a clinched edge. There are a number of predefined belt executions with different pitches and material dimensions. The belt can also be provided with side plates or flights.

Great Wall Wire Belt is a perfect products with both durability and suitable open area. It is temperature resistance, which is popular in the baking conveying applications. The flat surface of honeycomb conveyor belt supplies stable conveying during using. Honeycomb belts are used in production processes with temperatures of -30ºC up to +400ºC in food and other industries.

Materials Avaiable

Belt Edges Types

Product Specifications

Standard Duty Clinched Selvage Belting

| Width | Max. Tension | Approx. Wgt. | |||

| Design | Mesh | Min | Max | (Lbs./Ft. of width)1 | (Lbs./Sq. Ft.) |

| S1 | 1" x 1" | 4.5" | 240" | 480 | 1.85 |

| S3 | ½" x 1" | 4.125" | 240" | 660 | 2.20 |

| S7 | ½" x 1 Modified | 4.125" | 240" | 660 | 2.50 |

| S8 | ¾" x 1" | 4.5" | 240" | 550 | 2.00 |

STANDARD DUTY BELT DIMENSIONS:

• Flat strip = 3/8" wide x .046" thick, round edge • Connector rod = 11 gauge (.120" diameter)

• 12 gauge (.105" diameter) rods are available for S1, S3 and S7 designations.

• S8 belting is stocked in 20" and 30" widths, galvanized only. Other widths and materials available by special order.

Standard Duty Welded Selvage Belting

| Width | Max. Tension | Approx. Wgt. | |||

| Design | Mesh | Min | Max | (Lbs./Ft. of Width)1 | (Lbs./Sq. Ft.) |

| S2 | 1" x 1" | 3" | 240" | 480 | 1.85 |

| S4 | ½" x 1" | 3.25" | 240" | 660 | 2.20 |

| S5 | TRUE ½" x ½" | 3" | 240" | 750 | 3.25" |

| S6 | ½" x 1" MODIFIED | 3.25" | 240" | 660 | 2.50 |

STANDARD DUTY BELT DIMENSIONS:

• Flat strip = 3/8" wide x .046" thick, round edge • Connector rod = 11 gauge (.120" diameter)

• 12 gauge (.105" diameter) rods are available for all designations.

Heavy Duty Welded Selvage Belting

| Width | Max. Tension | Approx. Wgt. | |||

| Design | Mesh | Min | Max | (Lbs./Ft. of Width)1 | (Lbs./Sq. Ft.) |

| H1 | 1" x 1" | 3" | 192" | 1350 | 3.50 |

| H2 | ½" x 1" | 4" | 192" | 1750 | 3.90 |

| H3 | ½" x 1 Modified | 6" | 192" | 1750 | 4.85 |

| NNH3 | ½" x 1 Modified | 6" | 192" | 2000 | 5.00 |

HEAVY DUTY BELT DIMENSIONS:

• Flat strip = 1/2" wide x .062" thick, round edge • Connector rod = 6 gauge (.192" diameter), high tensile strength

Heavy Duty Clinched Selvage Belting

| Width | Max. Tension | Approx. Wgt. | |||

| Design | Mesh | Min | Max | (Lbs./Ft. of Width)1 | (Lbs./Sq. Ft.) |

| H4 | 1" x 1" | 10" | 192" | 1350 | 3.55 |

| H5 | ½" x 1" | 10" | 192" | 1750 | 3.95 |

HEAVY DUTY BELT DIMENSIONS:

• Flat strip = 1/2" wide x .062" thick, round edge • Connector rod = 6 gauge (.192" diameter), high tensile strength

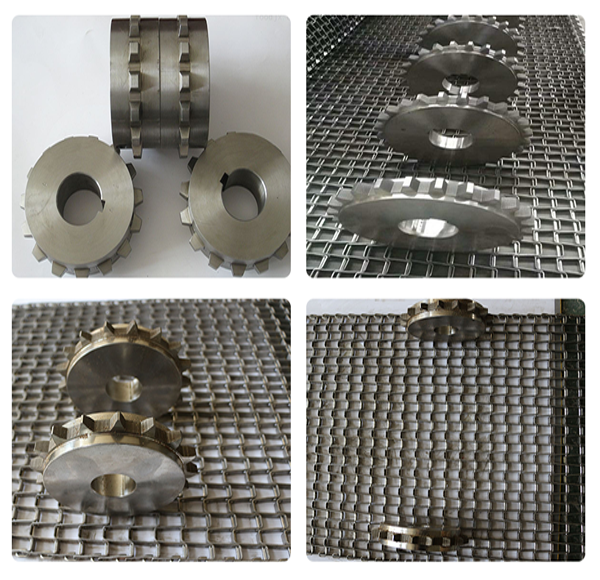

Great Wall Wire Belt Drive Components

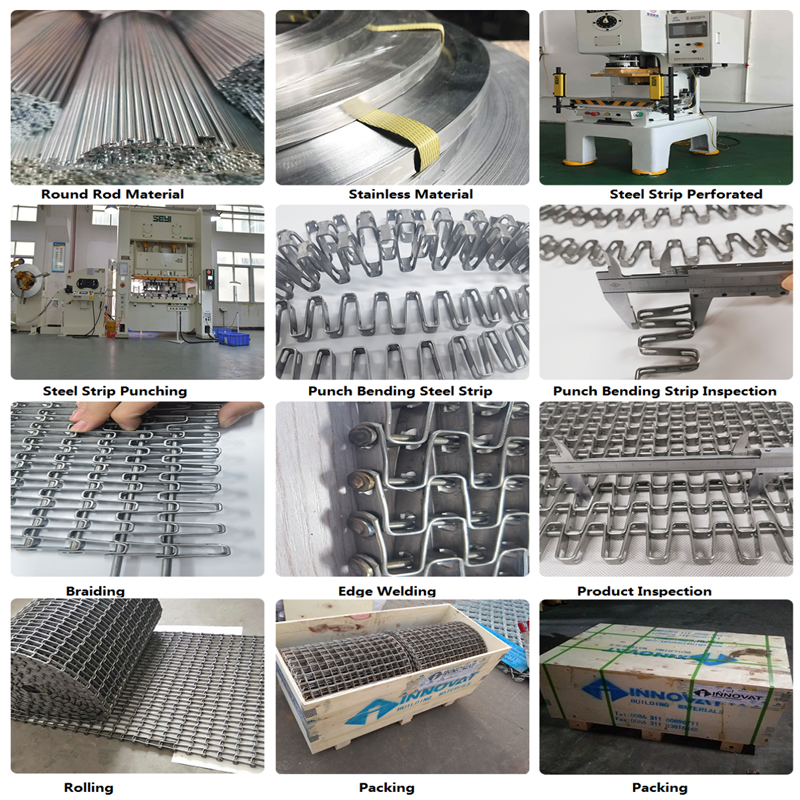

Production Process

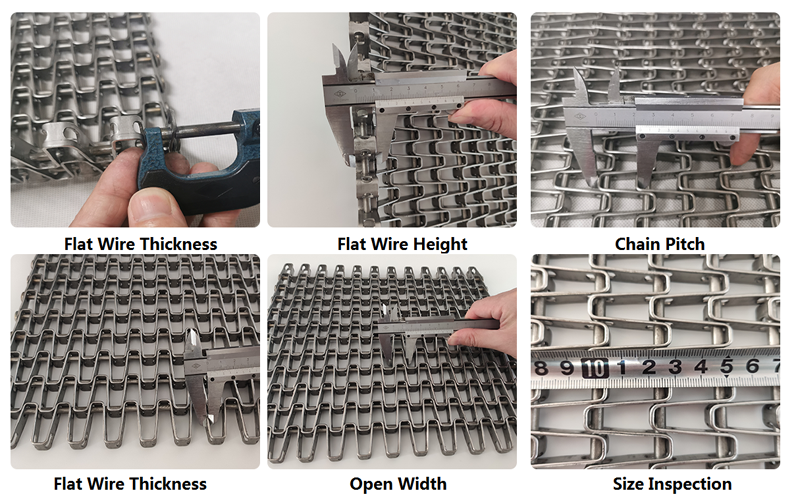

Product Inspection

Product Features

·Large open area for excellent air circulation.

·Optional side plates, reinforcing links and flights.

·Strong edge avoids snagging or catching even there are conveyor protrusions.

·Low maintenance.

·Suitable for friction or sprocket drive.

·Anti-slipping and last for years if used well.

·Durable structure prevents belt from deforming under heavy loads.

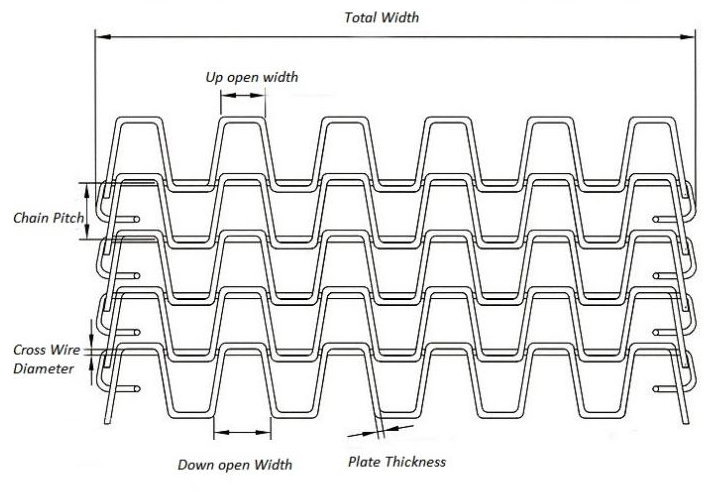

Quotation Parameters

·Material

·Plate Thickness

·Up Open Width

·Down Open Width

·Cross Rod Diameter

·Cross Rod Pitch

·Size

Product Application

·Food baking, cooling and freezing, etc.

·Chemical industry.

·Agricultural farming and harvesting.

·Being used in discharging tower at ports.

·Sorting, sieving and waste handling system.

·Washing, drying, painting and transferring.

·Acting as matting and drag mats.

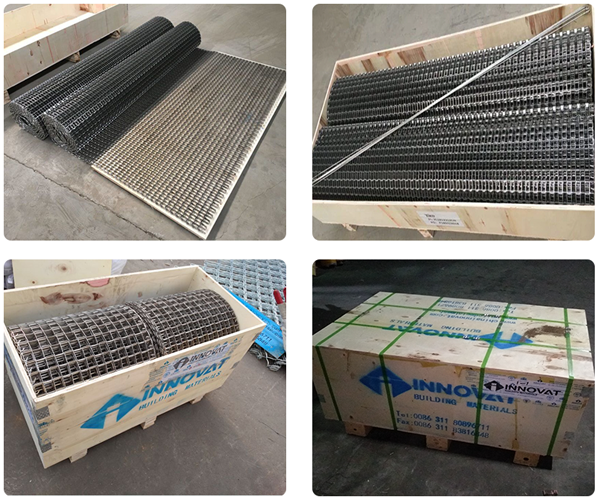

Package & Shipment

n